Dialysis Pressure Sensor

This project included part design for multiple manufacturing processes, as well as specifying off the shelf parts and working with vendors. The assembly includes hardware and disposable components, and integration into both systems was required. Due to application, accuracy requirements were very tight.

Overview

Problem Statement

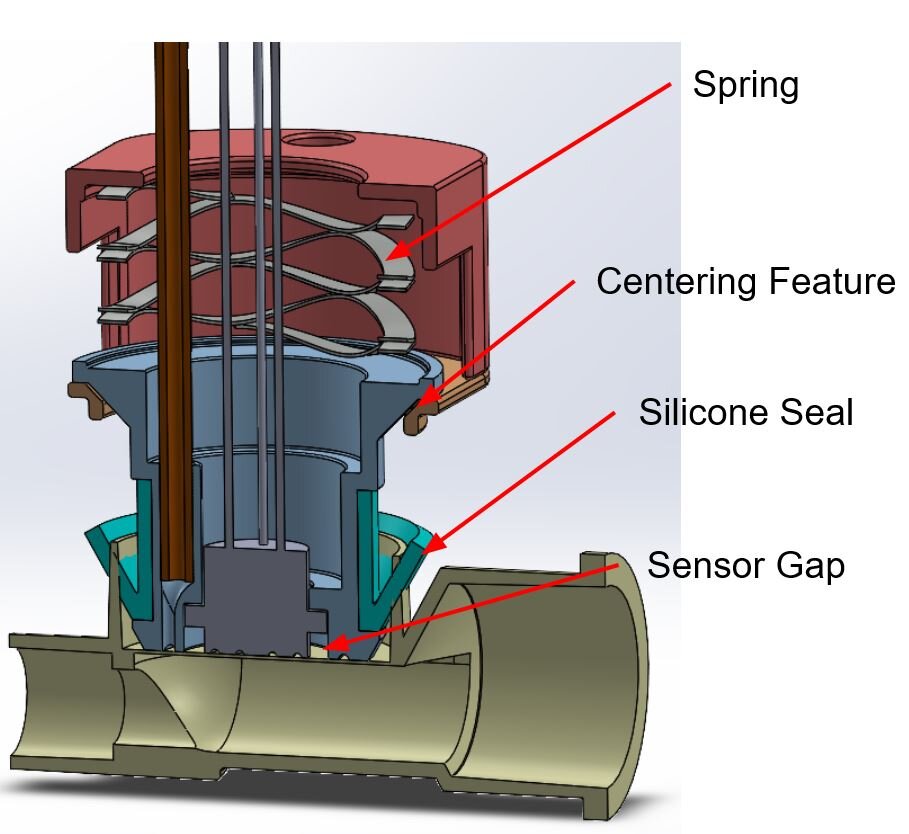

This subsystem was used within a dialysis machine. Multiple sensors were used to control pumps, valves, and ensure safety to the patient. The disposable portion of the design was loaded onto it’s interfacing hardware automatically, so the interface must be robust and repeatable. Both positive and negative pressures must be read through a membrane to avoid contamination to system.

Challenges

Non-contact measurements mean disposable tolerances play a role in measurement system accuracy. Dialysis application demands robustness of design. Peristaltic pumps used in system lead to cyclic loading and water hammering effects on sensors. 14 sensors per system made automated disposable loading a challenge. Negative pressure readings through a membrane require vacuum seal.

Results

This design proved viable and is currently in use.

Patents

Wyeth, M. T. W., Brugger, J. M. B., & McDermott, A. G. M. (2020). Pressure measurement devices, methods, and systems (WO2020190635A1). WIPO (PCT).